| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF,EXW |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 60 Days |

Basic Info

Model No.: GJCNC-BP-30

Additional Info

Packaging: Seaworthy packing

Productivity: 20Sets/Month

Brand: Euro-Asia/Gaoji

Transportation: Ocean

Place of Origin: Shandong, China

Supply Ability: 200Sets/Year

Certificate: ISO

Port: Qingdao

Product Description

Function features:

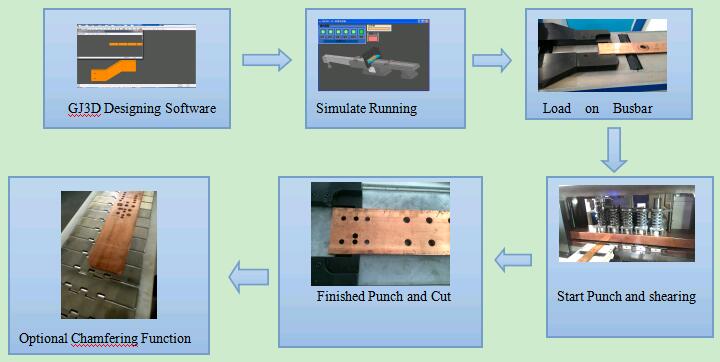

GJCNC-BP series CNC busbar punching & shearing machine is the computer-controlled equipment of high efficiency and high precision, specially used for busbar processing; Dies of punching, shearing are placed together in the storeroom of dies; It is capable of executing punching(round, oblong and other holes), shearing, slotting, round cornering and other processes; Automatic clamp switching can be achieved without manual intervention for longer busbars. Finished work pieces will be sent out through the conveyor. Such machine series can be used in combination with the CNC busbar bending machine to form an assembly line of busbar processing.

Advantages:

Technical parameter

Technical parameter

Description

Unit

Parameter

Press Force

Punching Unit

kN

500

Shearing Unit

kN

500

Embossing Unit

kN

500

X Max Speed

m/min

60

X Max Stroke

mm

2000

Y Max Stroke

mm

530

Z Max Stroke

mm

350

Stroke of Hit Cylinder

mm

45

Max hit speed

HPM

□120 □150

Tool

Punching Mould

set

□6 □8

Shearing Mould

set

□1 □2

Embossing Mould

set

□1

Control Axis

□3 □5

Hole Pitch Accuracy

mm/m

±0.20

Max hole punch size

mm

Φ32( Thickness of Copper bar <12mm)

Max embossing area

mm²

160×60

Max Allowable sheet dimension(L*W*H)

mm

6000×200×15

Total power

kw

14

main machine dimension:L*W

mm

7500X2980

Total weight

kg

7600

Packing details:

1) Applying Anti-Rust Oil

2) Covering with stretch film

3) Covering aluminum air bag

4) Vacuuming air bags

5) Boxing all the pallet

6) Loading to the container

CONTACT US

JINAN EURO-ASIA INT'L CO., LTD

Contact Person: James

Phone:86-0531-81670640

Fax:

Address: Rm211,No.145 Wenhua Est Rd, Jinan City, Shandong Province, China,Jinan,Shandong