| Unit Price: | USD 10000.0000 - 30000.0000 / Piece/Pieces |

|---|

Basic Info

Model No.: EMAC-BB

Marketing type: New Product 2020

Mechanical test report: Not Available

Video factory inspection: Provided

Core component warranty period: 1 Year

Core components: Bearing, Motor, Pump, Gear, PLC, Pressure vessel, Engine, Other, Gearbox

Old and new: New

place of origin: China

degree of automation: Automatic

Additional features: Machining

Certification: ce, CE

warranty period: 1 Year

Out-of-warranty service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Core selling point: High-accuracy

Applicable industry: Manufacturing Plant, Construction works, Printing Shops, Retail, Advertising Company

Where to provide local services (in which countries are there overseas service outlets): none

Showroom location (in which countries are there sample rooms overseas): none

Suitable for: Aluminum

Condition: New

Automation: Automatic

Type: Cnc Bending Machine

Additional Info

Packaging: Seaworthy package

Productivity: 20pcs/month

Brand: EA

Transportation: Ocean

Place of Origin: Shandong, China

Supply Ability: 20pcs/month

Port: Qingdao Port

Product Description

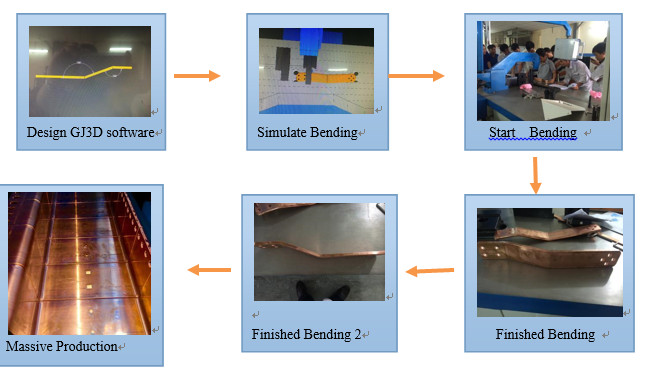

Product feature:

CNC busbar bending machine is the computer-controlled equipment dedicated for busbar bending,

performing various bending operations through the coordination of X-axis and Y-axis movements, assisted with manual feeding. The selection of different dies can complete the

plane bending, side bending and other processes of busbar. The machine can be used in combination

with GJ3D software, and is able to accurately calculate the spread length of the bend. As to the

frequently bent workpiece, it can automatically find the bending order to achieve programming

automation, simulate the bending order to place busbar and avoid errors in determining the bending positions.

Advantages :

1. Whole Assembled Shipment . No need On-Site Installation and commission !Working Flow:

Specification:

|

Item |

Unit |

Parameter |

|

Nominal Force |

KN |

400 |

|

Bender Accuracy |

Degree |

±0.3° |

|

Max bending Stroke |

mm |

250 |

|

Stroke of side striker |

mm |

2000 |

|

Max Moting Speed of Side striker(X Axis) |

m/min |

15 |

|

Bending Head(Y Axis) |

m/min |

Fastest 5; low: 1.25 |

|

Min inner Width of U-shape bend |

mm |

40(Note:Please consult us for smaller dimensions) |

|

Max bending angle |

degree |

90 |

|

Level bending (W*H) |

mm |

200X15 |

|

Vertical Bend(W*H) |

mm |

125×15 |

|

Total power |

kw |

7.2 |

|

Main machine dimension:L*W |

MM |

4150X1590 |

|

TOTAL Weight |

kg |

2700 |

Configuration:

|

Control Section |

||

|

Serial No. |

Name |

Brand Name |

|

1 |

Programmable Control |

OMRON |

|

2 |

Sensor |

Telemacanique From Schneider |

|

3 |

Control Button |

OMRON |

|

4 |

Touch Screen |

OMRON |

|

5 |

Computer |

Lenovo |

|

6 |

AC Contactors |

ABB |

|

7 |

Circuit Breaker |

ABB |

|

8 |

Servo Motors |

YASKAWA(Japan) |

|

9 |

Servo Drivers |

YASKAWA(Japan) |

|

10 |

Control software and Three-dimensional |

Gaoji Busbar Processing System(GJ3D) |

|

computer-aided design |

||

|

Transmission System |

||

|

Serial No. |

Name |

Brand Name |

|

1 |

Precision Straight rail |

Taiwan HIWIN |

|

2 |

Precision Ball Screw |

Taiwan HIWIN |

|

3 |

Bearing |

Japan NSK |

3D Drawing Software (Bus bar Design to Finished Piece At one Time)

Auto Compensation System

Fast but Energy Saving!

High Efficiency!

CONTACT US

JINAN EURO-ASIA INT'L CO., LTD

Contact Person: James

Phone:86-0531-81670640

Fax:

Address: Rm211,No.145 Wenhua Est Rd, Jinan City, Shandong Province, China,Jinan,Shandong